Acoustic Barriers: Innovative Solutions for Effective Noise Control

Introduction

In today’s increasingly noisy world, controlling sound pollution and vibrations is more important than ever. Whether in industrial settings, automotive design, construction, or domestic applications, managing sound transmission and vibration is critical for safety, comfort, and compliance with regulations. One of the most effective tools in the soundproofing arsenal is acoustic barriers — specialized barrier products designed to reduce airborne noise and impact sounds.

This article explores the versatile world of acoustic barriers, their types, applications, and the benefits they bring across various industries. We will also touch on related technologies like foam conversion that complement acoustic barriers to create custom noise-control solutions.

Understanding Acoustic Barriers and Their Role

Acoustic barriers are flexible, sound-insulating materials specifically engineered to block and reduce sound transmission between spaces. Unlike simple sound absorbers, these barriers prevent the passage of noise by adding mass and damping vibrations, thus reducing transmission loss — the measure of sound prevented from passing through a structure.

These barriers are often supplied as sheets or custom-cut pieces that can be tailored to fit complex or curved surfaces, making them highly adaptable. Their construction includes various materials such as polymeric membranes, bitumen layers, aluminum foils, and mineral fillers, each designed to excel under different environmental conditions and frequencies.

In addition to soundproofing, acoustic barriers often double as anti-vibration pads, absorbing impact sounds caused by machinery or moving vehicles. This dual functionality is crucial in applications ranging from automotive cabins to heavy construction vehicles.

Types of Acoustic Barrier Products

The diversity of barrier products available allows for tailored solutions to specific noise problems:

1. Polymeric Acoustic Barriers

Examples like C03 and C09 are low-density vinyl membranes loaded with natural fillers. These materials are free from harmful substances such as lead or bitumen, making them environmentally safer options. They are especially effective when bonded intimately to existing panels made of wood, metal, or plastic, improving sound insulation across a broad frequency range.

2. Bitumen PE Foil Covered Barriers

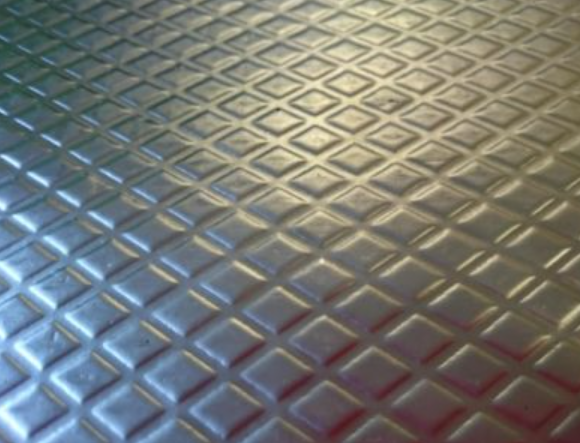

Products like C022 and C023 combine bitumen-based sound insulation with a protective polyethylene foil that prevents oil seepage and keeps the surface clean. These diamond-embossed barriers have self-adhesive backing for easy application and excel at vibration damping and blocking transmission loss on flat surfaces.

3. Bitumen Aluminium Acoustic Barriers

The C024 barrier includes a laminated bitumen, polymer, and mineral filler layer protected by an aluminum foil facing. This makes it highly heat-resistant and suitable for engine compartments in cars, agricultural vehicles, construction machinery, and marine environments where thermal conditions are challenging.

Complementing Acoustic Barriers with Foam Conversion

While acoustic barriers block and dampen sound, foam conversion processes create tailored foam products that absorb sound waves, further enhancing acoustic control.

Foam materials such as polyurethane, polyethylene, and polystyrene are transformed using cutting, molding, laminating, and fabricating techniques to produce custom shapes and sizes. These foam products are ideal for applications needing sound absorption, thermal insulation, or cushioning.

Foam conversion capabilities include:

- Die-cutting and water jet cutting for precise shaping.

- Lamination to combine foam with barrier sheets.

- Profiling and molding to produce complex geometries fitting diverse applications.

Together, acoustic barriers and converted foams form laminated solutions that address both sound absorption and transmission loss, crucial in spaces like engine rooms, lift cabins, metal furniture, and pipe insulation.

See also: How Online Bookkeeping Can Save Time and Money for Small Businesses

Applications Across Industries

Acoustic barrier products find use in many sectors:

- Automotive: Reducing engine noise, vibration, and improving cabin comfort with lightweight soundproofing layers.

- Construction: Noise control in machinery enclosures, HVAC systems, and building interiors.

- Domestic Goods: Quieter home appliances and power tools through embedded acoustic barriers.

- Marine and Boats: Heat-resistant soundproofing materials for engine rooms and decks.

- Industrial Acoustics: Reducing workplace noise for safer, more productive environments.

- Medical: Specialized foam components and barriers designed for healthcare equipment and orthopedics.

- Military Vehicles: High-specification fire-resistant acoustic materials for safety and stealth.

Key Benefits of Acoustic Barriers and Barrier Products

Choosing the right acoustic barrier products provides a wide array of benefits:

1. Superior Sound Insulation

By adding mass and damping properties, acoustic barriers effectively reduce airborne noise and impact sounds, improving sound privacy and comfort.

2. Vibration Dampening

Many barrier products function as anti-vibration pads, minimizing structure-borne noise and protecting sensitive machinery from damage.

3. Customizability and Flexibility

Acoustic barriers are available in various thicknesses and materials and can be custom-cut to fit complex or curved surfaces, ensuring seamless integration.

4. Thermal Resistance

Certain barriers, especially those with aluminum facing, withstand high temperatures, making them suitable for harsh environments like engine compartments.

5. Environmental Safety

Modern polymeric barriers are free from lead and harmful oils, aligning with environmental and health regulations.

6. Ease of Installation

Self-adhesive backing on many products simplifies application, reducing installation time and costs.

7. Enhanced Acoustic Performance Through Lamination

Combining barriers with acoustic foam creates laminates that tackle both sound absorption and transmission loss, offering comprehensive noise control.

Conclusion

Incorporating acoustic barriers into noise control strategies is vital for businesses and industries aiming to create quieter, safer, and more comfortable environments. From automotive cabins to construction machinery, these flexible barrier products address complex acoustic challenges by reducing noise transmission and dampening vibrations.

By combining acoustic barriers with foam conversion products, companies can develop bespoke solutions tailored to their unique needs — whether it’s reducing engine noise, controlling vibrations, or insulating pipes and metal surfaces. The versatility, customization options, and proven performance of these materials make them indispensable in modern soundproofing efforts.

If your business faces noise challenges, exploring acoustic barriers and foam solutions is a step toward effective sound control. Contact Acoustafoam or similar industry experts today to discuss tailored acoustic barrier products designed to meet your specifications and improve your operational environment.